Lindstrom has been a leading brand for cutters for over 165 years, trusted by professionals across industries for their precision and reliability.

High-Quality Materials: Made from premium materials ensuring durability and long-term performance.

Precision Engineering: Meticulously engineered to provide precise cutting, even on delicate materials, preventing damage to the material being cut.

Comfort and Ergonomics: Designed with ergonomics in mind, featuring comfortable handles and lightweight construction, reducing hand fatigue during prolonged use.

Consistency and Reliability: Known for their consistent performance and reliability, making them a trusted choice among professionals who require precision tools for their work.

Wide Range of Options: Various sizes and types available to suit different cutting needs, ensuring there’s a cutter for every bench task.

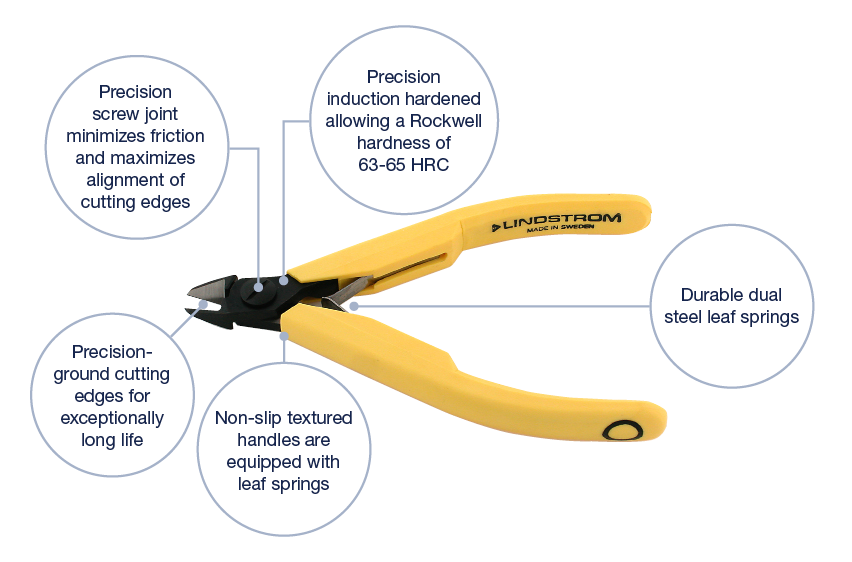

The original Lindstrom 80 Series Cutters, with classic yellow handles, offer unsurpassed cutting capacity, precise alignment of jaws, and durable, easily replaceable dual steel leaf springs.

Oval Head Cutters from Lindstrom are the most common shape, offering the greatest strength and durability. They evenly distribute cutting impact, making them suitable for a wide variety of jewelry applications.

The Cutting Edge Style:

Lindstrom offers Microbevel, Flush, and Ultra-Flush cutters with an Oval Head. Let’s take a look at the features of each, and our most popular styles.

Micro-Bevel cutters provide a low profile cut result, important for solderability and connectivity.

The 8160 is a larger size head and can handle thicker wire and more demanding jobs, rated from 12 ga to 26 ga on soft wire.

Flush Cut leaves a narrow and short peak along the “pinch” line, reducing the surface area at the cut. Flush cutters offer a nice balance of precision and strength, reducing lead-shock.

The 8141 features a small head size, perfect for getting into tight spots. This style is very popular in jewelry making and can cut precious metal wires from 16 ga to 38 ga.

Ultra-Flush cutters provide the most precise cut result available, ideal for close tolerance needs, cutting jump rings that can be soldered instantly.

The 8142 style also boasts a small head size, designed for use in close tolerance jewelry production, where a clean edge is crucial. This model is ideal for any situation where filing is difficult or too time consuming and can cut wires from 18 ga to 38ga.

Use the Right Cutter for the Job: Make sure you select the appropriate cutter for the wire you are cutting. For example, use flush cutters for a clean, flush cut. Also, make sure to choose heavy-duty cutters for thicker wires (If you cut wire that is too thick for the cutter, you risk breaking the tips!)

Positioning: Hold the cutter at a right angle to the wire to ensure a clean, straight cut. Avoid cutting at an angle, as this can lead to a jagged edge.

Cut Close to the Work: Cut as close to your work as possible to minimize the length of wire wasted.

Use Smooth, Even Pressure: Use smooth, even pressure when cutting to avoid crushing the wire and to achieve a clean cut.

Use Protective Gear: We recommend wearing safety glasses to protect your eyes from any small pieces of wire that may fly off during cutting.